Press Releases

JAMSTEC

National Agriculture and Food Research Organization

Soft and sturdy fiber optic device for real-time 3D visualization of crop root growth

— A non-destructive, ultra-sensitive monitoring technology for small-scale biological movements underneath the soil surface

Summary:

- ◆

- Distributed fiber optic sensing is an emerging radar-like technology that can be used to acquire temperature, strain, and acoustic data.

- ◆

- A novel imaging strategy was developed to track plant root growth in soils using a distributed fiber optic sensing device.

- ◆

- The new strategy can be applied to any small-scale perturbation occurring in solids, such as the movement of worms through sediments and the propagation of mushrooms in loam.

Description:

More than 25% of Earth’s population was affected by moderate to severe food insecurity in 2020. Under the dual pressures of an increasing global population size and climate change, we must develop a resilient and productive crop system to combat the rising threat of food insecurity. Recent studies have shown that plant root architecture determines crop resilience and productivity (Uga Y. et al. 2013). For example, deep root structures improve drought resistance and maintains high crop yields even without rainfall. Conversely, shallow root structures are advantageous for growth in oxygen-deficient saline paddy fields. To accelerate the adaptation of crops to expected environmental phenomena, such as droughts and floods, a platform that can rapidly provide real-time feedback on plant root architecture is needed. However, this critical organ grows invisibly underground and is notoriously difficult to track. Visualizing plant roots in the field requires digging, which is both time-consuming and destructive. Thus, studying plant root structures has been challenging due to a lack of convenient and high-resolution underground imaging methods.

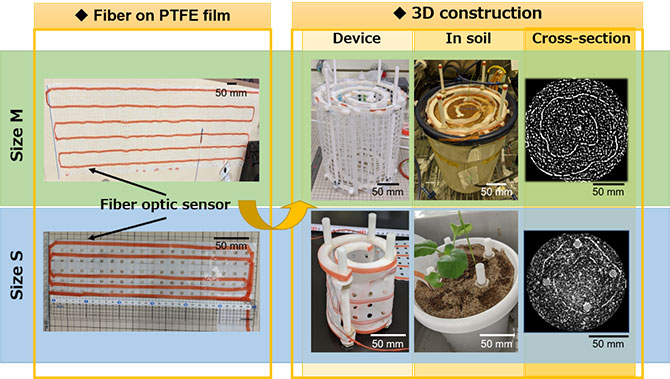

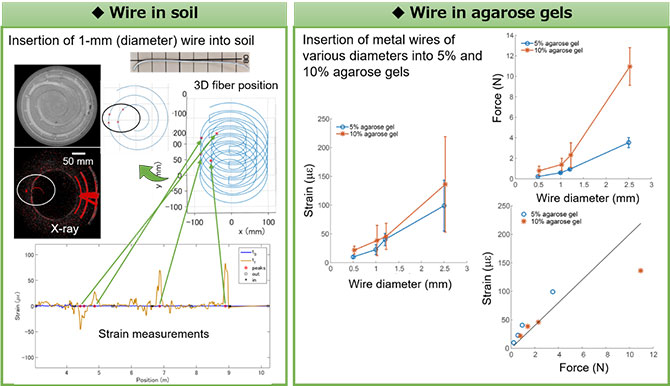

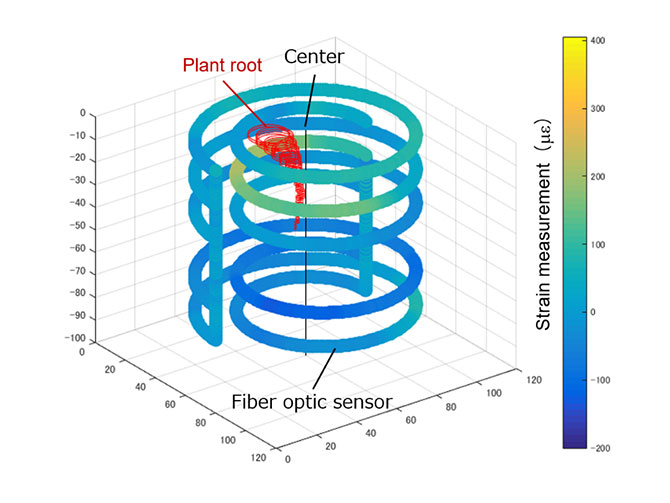

With funding from the Japan Science and Technology Agency’s CREST Program and the Moonshot Research and Development Program, researchers from Japan Agency for Marine–Earth Science and Technology (JAMSTEC) and the National Agriculture and Food Research Organization (NARO) are now prototyping novel imaging devices that can track plant root growth underground via distributed fiber optic sensors. By formulating a fiber optic sensor into a soft yet sturdy polytetrafluoroethylene (PFTE) film structure (Figure 1), they have demonstrated that the original device could detect and monitor small movements within solids (Figures 2 and 3). The original fiber-radicle-gadget (Fiber-RADGET) offers a novel method for imaging small movements in the field.

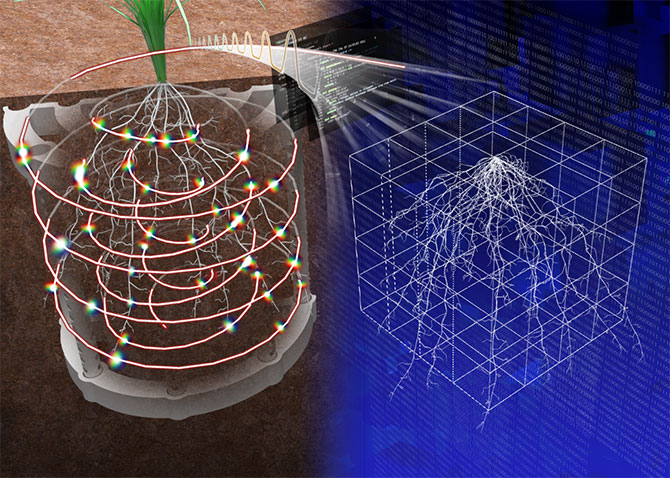

Agricultural technology is increasingly becoming automated with seamless feedback through Internet-of-Things remote sensors. The novel device highlighted here represents a significant addition to the repertoire of tools that next-generation agriculturalists can use for data-driven automation (Figure 4). A joint patent application was filed by JAMSTEC and NARO with Japan Patent Office for the related inventions.

Reference:

Uga Y, Sugimoto K, Ogawa S, Rane J, Ishitani M, Hara N, Kitomi Y, Inukai Y, Ono K, Kanno N, Inoue H, Takehisa H, Motoyama R, Nagamura Y, Wu J, Matsumoto T, Takai T, Okuno K, Yano M. Control of root system architecture by DEEPER ROOTING 1 increases rice yield under drought conditions. Nat Genet. 2013 Sep;45(9):1097-102. doi: 10.1038/ng.2725.

Figure 1. Fabrication of Fiber-RADGET. The fiber optic sensor was glued to a soft and sturdy PTFE film and molded into a spiral. The device was then set in a pot and filled with soil. The spiral configuration of the fiber optic sensor was confirmed by cross-sectional X-ray images.

Figure 2. Metal wire detection in soil and agarose gels. For the soil experiment, a wire with a diameter of 1 mm was inserted into the soil ~50 mm left from the center. The wire appears red in the X-ray image and its location is indicated by the white circle, which coincides with the locations of strain peaks recorded by the fiber optic sensor. For agarose gel experiments, the wire diameter and agarose concentration varied. The larger strain was correlated with a larger wire diameter and higher agarose concentration due to the stronger force associated with insertion.

Figure 3. Monitoring plant root growth in the soil. Fiber-RADGET was set inside a small pot and filled with soil and then a radish seed was planted at the center. After 3 weeks of growth, the pot was imaged in an X-ray CT scanner and the location of the radish root was identified. Root expansion corresponded with the higher strain measurements recorded by the fiber optic sensor.

Figure 4. Application of Fiber-RADGET to reconstruct plants as a 3D model in cyber space for next-generation, data-driven agricultural production.

Contacts

- (For this study)

- Mika Tei, Scientist, Institute for Extra-cutting-edge Science and Technology Avant-garde Research (X-star), Advanced Science–Technology Research (ASTER) Program, JAMSTEC

- (For press release)

- Public Relations Section, Marine Science and Technology Strategy Department, JAMSTEC