When we drill a hole, the drill bit and the drill pipe are hung from the derrick of the ship. The combined weight of the drill pipe (weight on bit), along with the rotation of the drill bit, act to help the drill bit to cut into the formation. The drill bit is equipped with special nozzles, which direct drilling mud under pressure in jets, to clear out the hole, lubricate and cool the drill bit, and increase efficiency of drilling.

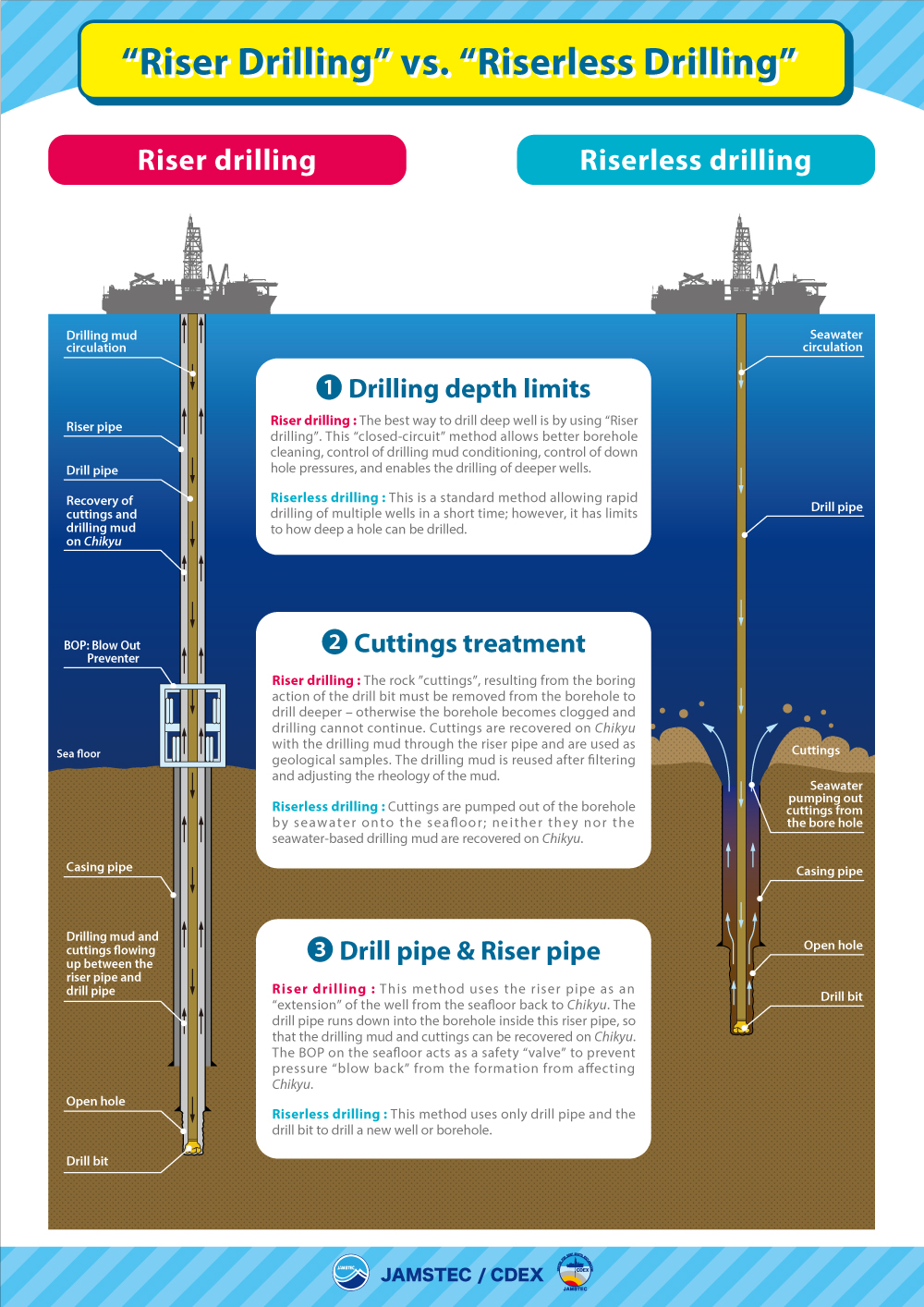

Depending on the ultimate depth of the hole being drilled, combined with the purpose of the hole (and water depth limits), there are two main methods of drilling: “Riser drilling” or “Riserless drilling” for Chikyu while offshore.

The main difference between “Riser drilling” and “Riserless drilling” is that Riser Drilling requires special riser pipe connected to a BOP (Blowout Preventer) on the seafloor. Riser pipe connect (through the BOP) the downhole well being drilled and Chikyu. This creates a closed-system for drilling mud, so that the mud weight can be carefully controlled, while all the “cuttings” – rock that needs to be removed from the well to drill deeper – are returned to Chikyu. This increases the safety and efficiency of drilling, but is limited to 500-2,500 m water depth. Riserless drilling uses only the drill bit and drill pipe, so cuttings remain on the sea floor.

According to the drilling program, special steel pipe, called casing pipe, can be installed into the drilled hole, protecting the borehole walls from collapsing, and therefore enables drilling the hole deeper. Each casing pipe runs through the previous casing pipe, and this results in the borehole size decreasing with every successive casing pipe.

Coring, or collecting special 9.5 m long sections of rock samples, is used for geological evaluation. Using special geophysics tools to make measurements of the rock while drilling, called LWD (Logging While Drilling), is one way to collect geological data for drilling operations quality control and also for scientific objectives.

Glossary

[1] Drill bit : The cutting tool at the bottom of the drill pipe which bores into the formation. There are many different types and styles of cutting faces and materials used for drill bits, and these are tailored for specific types of rock, or formations. Drill bits range in size from 3-3/4” (95.25 mm) to 36” (914.4 mm), and drill bit sizes are limited by the kind of casing pipe used to keep the well from collapsing. Roller Cone-type and PDC (Polycrystalline Diamond Compact)-type bits are most commonly used.

[2] Drill pipe : Drill pipes are the metal pipes that add weight and length above the drill bit. These include special types such as drill collars which add extra weight and strength. These are classed by length, inside and outside diameter, and the material used in their construction. The inside diameter of the drill pipe on Chikyu is larger than usual to accommodate the Chikyu wireline coring system.

[3] Drilling Mud : Drilling mud, or “Drilling Fluid” is liquid pumped down through the inside of drill pipe, and out the drill bit, to cool the drill bit from the friction from drilling rock, clean the borehole of cuttings, and also create a protective covering on the borehole walls to help prevent borehole wall collapse. Different mixes are used for Riser drilling and for Riserless drilling. Riser drilling requires adjustments of rheology and specific gravity (density) of the drilling mud. Riser drilling requires a much more complex mixture of special chemicals which are recovered on Chikyu, cleaned and re-used by separating out the cuttings from the drilling mud. Riserless drilling uses a seawater-based mud, without the expensive chemicals used for Riser drilling.

[4] BOP (Blowout Preventer) : This safety device for Riser drilling is designed to prevent unexpected fluid (Oil from the formation) or gas from coming up through the Riser and Drill pipe to the drill floor. It acts like a series of giant valves to isolate the borehole from the Riser pipe.

[5] Riser pipe : This special, large diameter, pipe is used to connect the BOP and the borehole to the ship. Different pipe sections are rated for different deployment depths, and are usually negatively buoyant. Drill pipe and drill pipe tools are run through the inside of the riser pipe. Drilling mud from the drill bit comes up through the space between riser pipe and drill pipe carrying cuttings. The operational water depth limit of Chikyu riser pipe is 2,500 m.

[6] Casing pipe : This special, large diameter steel pipe is used to keep the borehole from collapsing. This is also used to isolate different formations, which often have different pressures at depth. There are many different size, types, and materials used for casing pipes, designed for different pressures and operation needs.

[7] Coring : This operation collects geological samples from the formation. A special Coring bit is used to drill out a cylindrical core sample inside the drill bit and the coring tool assembly.

[8] LWD (Logging While Drilling) : This describes using special geophysical measurement tools, connected to the bottom of the drill pipe, and above the drill bit. These tools (there are many developed by industry) are used to measure and collect geological data in real time while drilling at the same time.