Time is a premium commodity during coring expeditions. Scientists hope to retrieve as much core sample as possible during these expeditions and eventually capitalize on the research results. The Tool Pusher carefully organizes tasks and closely monitors activities so as to avoid time losses caused by unexpected incidents or machinery failure. ‘Carelessness and over-familiarity can easily lead to incidents. Attention and alertness must be aroused every day’, says Kawasaki.

The Tool Pusher is attentive to nipping trouble in the bud. “Preventative Maintenance” programs are used to manage control equipment, which requires especially close attention since it cannot be readily replaced. Such continual efforts are essential for successful coring expeditions.

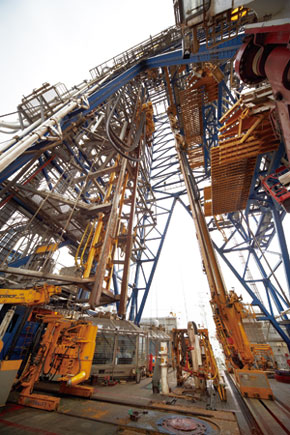

“I take pride in and feel good about my job, using world-class equipment aboard CHIKYU. When work proceeds without downtime or other inefficiencies, nothing is more rewarding”, comments Kawasaki. Research drilling has many phases in which new challenges and unexpected situations arise. They are an inherent part of the job. For that reason, preparations are repeated and alternatives, in case of emergency, are readied.

The Tool Pusher must keep watch on the entire drilling operation, from job preparation, through to execution, to contingency planning.

- |1|

- 2|