Even as Machinery Evolves, Nothing Can Replace Human Senses

The insistence on safety can be seen in the redundancy of the generators. CHIKYU has six 5,000 kW main generators and two 2,500 kW auxiliary generators on board. They are arranged along both sides of the ship, separated by watertight doors. This layout ensures that even if one side of the ship were to be rendered inoperable by an influx of water or some other eventuality, the remaining generators would still be able to provide the minimum amount of power required for the hull to maintain its position. Also, if a generator is stopped for maintenance while the ship is at sea, the number of generators would drop to four providing power and three as backups, meaning that in the worst case scenario it would not be possible to ensure the amount of power needed. Ensuring safety is of particular importance during drilling, so generator maintenance is carried out based around the drilling schedule.

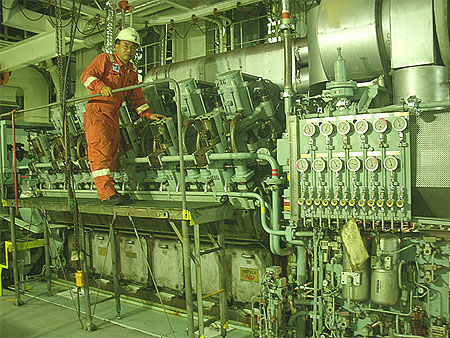

“Once a ship leaves port, the crew members have to handle repairs and any other necessary tasks,” says Horie. “Particularly in the case of CHIKYU, which is undertaking a major mission, there is an emphasis on being able to continue operations in a safe manner. In the engine room, we use our senses when operating the machinery and are always on the lookout to ensure that not even the slightest abnormality is overlooked.”

When the generators are running, the temperature in the engine room can climb to almost 40ºC. But having crew members in the engine room allows them to avert serious problems by immediately noticing a tiny oil leak, some vibration, a strange noise, or an unusual smell. Of course the machinery has built-in sensors that trigger an alarm if something is wrong, but Horie underscores the paramount importance of actually having someone on hand to notice what is happening.

This policy of keeping capabilities focused on-site allows a flexible response to any unexpected situation. CHIKYU uses seawater to cool its engines, but following the earthquake and tsunami disaster of March 11, 2011, huge amounts of flotsam were washed out to sea and this clogged up the cooling pipeline inlet filter. Left unchecked, this blockage would have eventually disabled the cooling system, causing the generators to shut down. This outcome was avoided by the engine-room crew taking the unprecedented measure of cleaning the filter of trash every 10 minutes, thereby ensuring that the ship’s electrical supply was not interrupted.

“Even though machinery is evolving rapidly and becoming more and more convenient to use, the basic principles never change much,” notes Horie. “Our aim is to pass on to the younger crew members the wisdom we have acquired by making use of all our senses and our experience.”

- |1|

- 2|