JAMSTEC > Research Institute for Value-Added-Information Generation (VAiG) > Center for Mathematical Science and Advanced Technology (MAT) > Member > Seyed Reza Amini Niaki

Members

r.amini

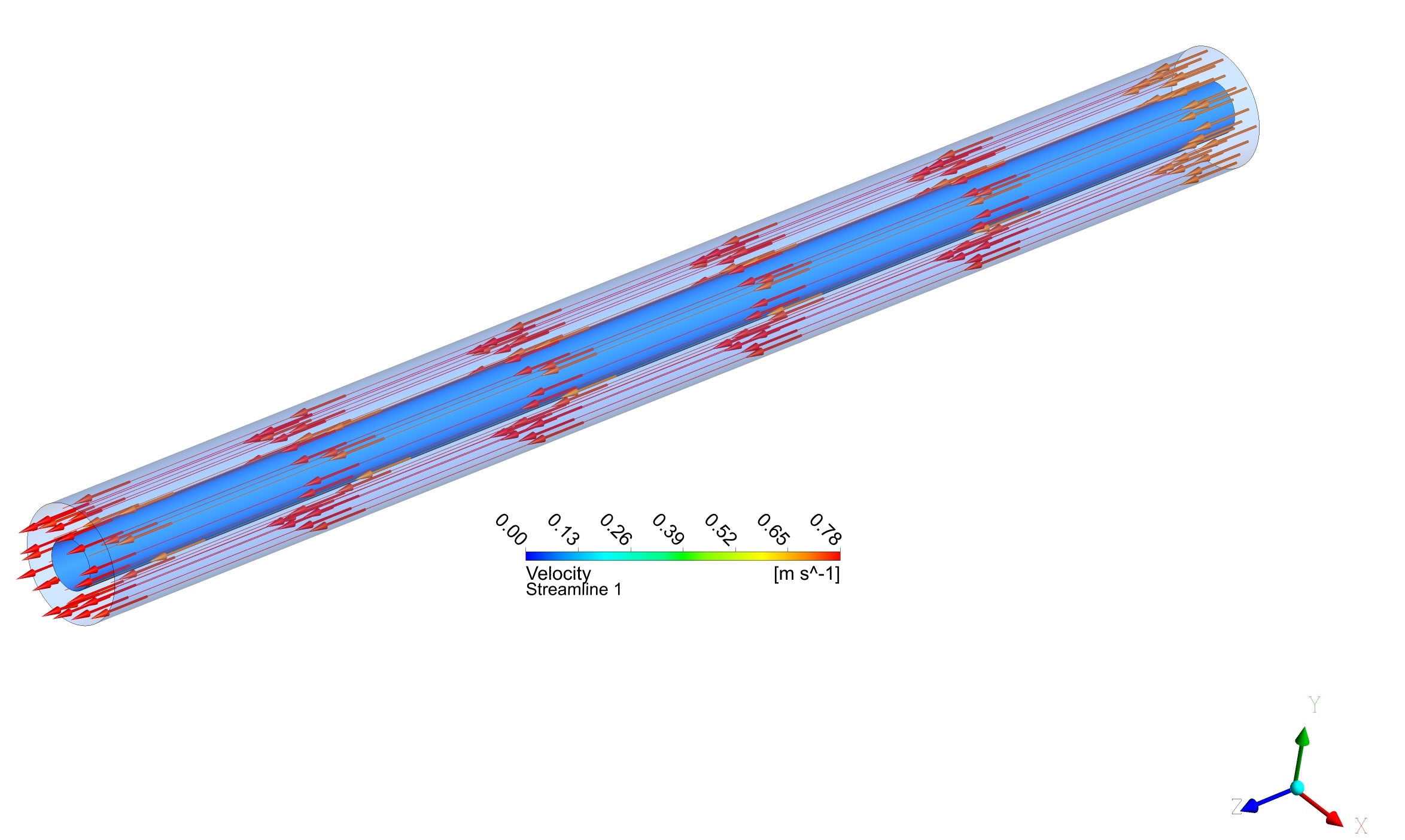

Fluid streamlines in the annular riser pipe

Seyed Reza Amini Niaki

Project Researcher

Project Team for Development of Production Technology for Deep Ocean Resources

Japan Agency for Marine-Earth Science and Technology

r.amini

Short CV

My primary research field is CFD modeling and analysis of the multiphase flow, specially gas-solid and liquid-solid flow with two-fluid modeling, where both phases are treated as interpenetrating continuum phases. Examples of multiphase flow related to my research work include slurry mud transportation and fluidized bed reactors.

Employment

| 2019.10 - Present | Project Researcher Project Team for Development of Production Technology for Deep Ocean Resources Japan Agency for Marine-Earth Science and Technology (JAMSTEC), Japan | 2018.12 - 2019.10 | Postdoctoral Research Center for Mathematical Sciences Applied to Industry (CeMEAI) National Agency of Petroleum, Natural Gas and Biofuels(anp), Petrobras University of Sao Paulo (USP), Brazil |

Education

| 2015.3 - 2018.11 | PhD in Mechanical Engineering,Thermal and Fluid, Multiphase Flow Lab. University of Sao Paulo (EESC-USP), Brazil |

Research Topics

- CFD simulation of slurry flow in annular pipelines

- Three-dimensional CFD modeling of single-phase and Liquid-solid two-phase slurry flows demonstrate in this research line. The flow domain consists of a vertically oriented annular pipe, and the CFD model in this area can be divided into the Eulerian-Eulerian model. This work aims to study the slurry flow (mud) as a non-Newtonian flow using CFD simulation and validate the simulation with experimental studies. For example, a pressure drop in pipe flow is the most significant variable in reducing the size and better selection of slurry pumps, especially the optimization of power consumption and the cost.

Fluid streamlines in the annular riser pipe

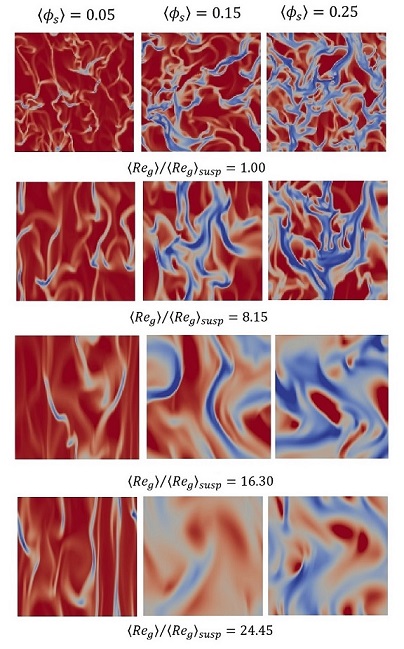

- Sub-mesh modeling of gas-solid flows in fluidized beds

- Fluidized bed reactors are widely applied in chemical and energy industries, and their design and scale-up are virtually empirical, costly, and time-consuming. This research line aims to the development of alternative theoretical tools and two-fluid modeling, where gas and particulate are both treated as interpenetrating continuum phases, has appeared as a most promising approach. Only filtered modeling approaches are feasible owing to the large domains to be resolved in real-scale fluidized bed reactors. Also, closure models become necessary to recover sub-grid effects that are filtered by the very coarse numerical grids that are imposed owing to computational limitations. It is proposed to investigate and model the effect of the Reynolds number on filtered parameters since the current state of the art in this line of development offers only models obtained under conditions of low Reynolds numbers. In addition, it is proposed to investigate the effects of collisional/frictional particle-particle interactions and the effects of gas turbulence on the meso-scale flow hydrodynamics. Computational experiments will be performed for ranges of domain average solid volume fractions from very diluted to very dense. The open computational code MFIX will be used in all simulations. The final objective pursued is the provision of new, increasingly realistic sub-mesh closure models for modeling two-fluid filtered gas-solid fluidized flows.

Plots of solid volume fraction in the domain inside the statistical steady state regime.

Publications

Selected Publications (Peer-Reviewed)

- “Some accuracy related aspects in two-fluid hydrodynamic sub-grid modeling of gas-solid riser flows”, Mouallem Joseph, Seyed R. A. Niaki, Norman Chavez-Cussy, Christian C. Milioli, and Fernando E. Milioli, AIChE Journal 66 (1) 2019, e16763.

- “Macro-scale effects over filtered and residual stresses in gas-solid riser flows”, Mouallem Joseph, Seyed R. A. Niaki, Norman Chavez-Cussy, Christian C. Milioli, and Fernando E. Milioli, Chemical Engineering Science 195 (2019): 553-564.

- “Picard-Newton iterative algorithm to solve the potential flow equation for different turbomachinery flow regimes”, Mouallem Joseph, Johny Mouallem and Seyed R. A. Niaki, Brazilian Society of Mechanical Sciences and Engineering 41 (8) 2019: 312.

- “On the effects of the flow macro-scale over meso-scale filtered parameters in gas-solid riser flows”, Mouallem Joseph, Norman Chavez-Cussy, Seyed R. A. Niaki, Christian C. Milioli, and Fernando E. Milioli, Chemical Engineering Science 182 (2018): 200-211.