Arctic Research Vessel Construction Current Status Ⅱ

July 21, 2023

Arctic Research Vessel Construction Team

It`s been almost a year since the last update on construction states.

How far have we made it?

Well, take a look at these images!

The shipyard (JMU), the construction supervisor (MOL), and the ship owner, JAMSTEC, have repeatedly held more intensive discussions over the past year.

Now, we`re excited to announce the design of the hull structure is almost completed!

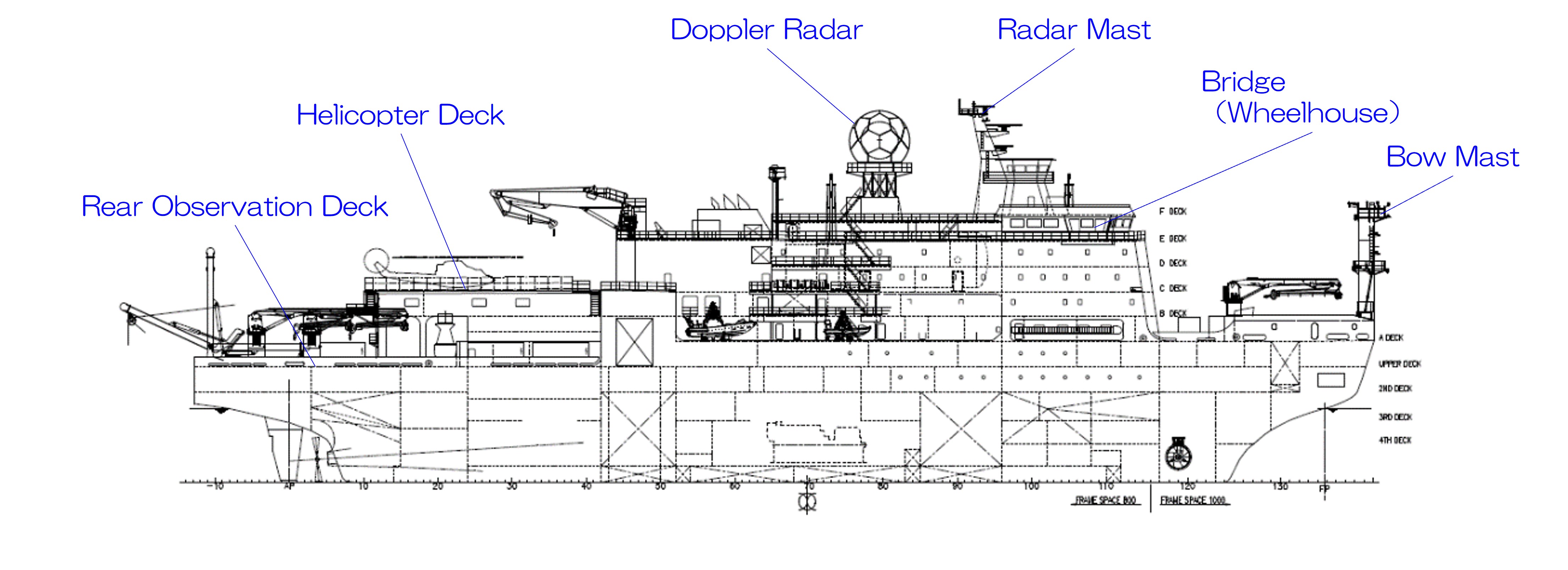

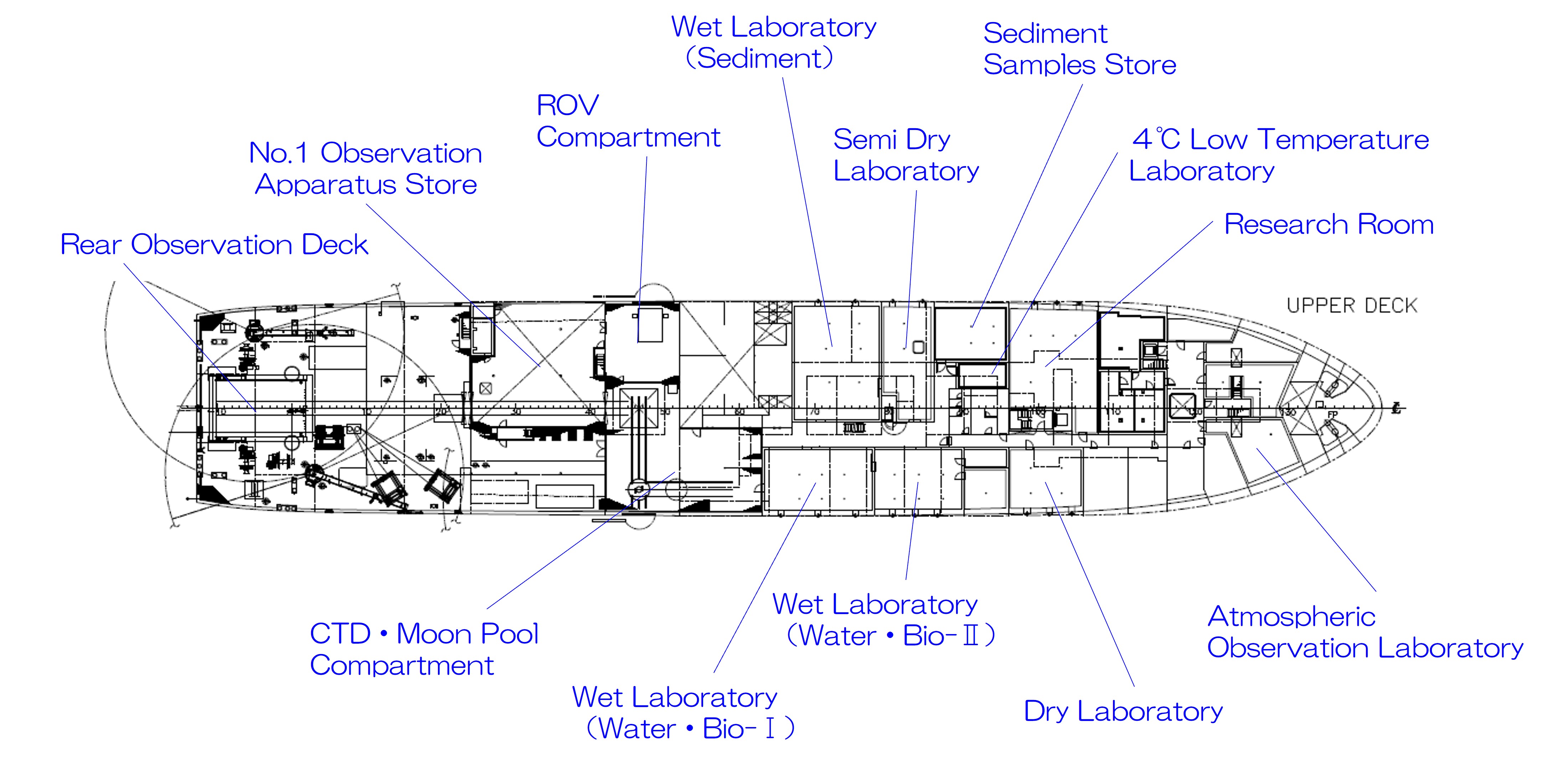

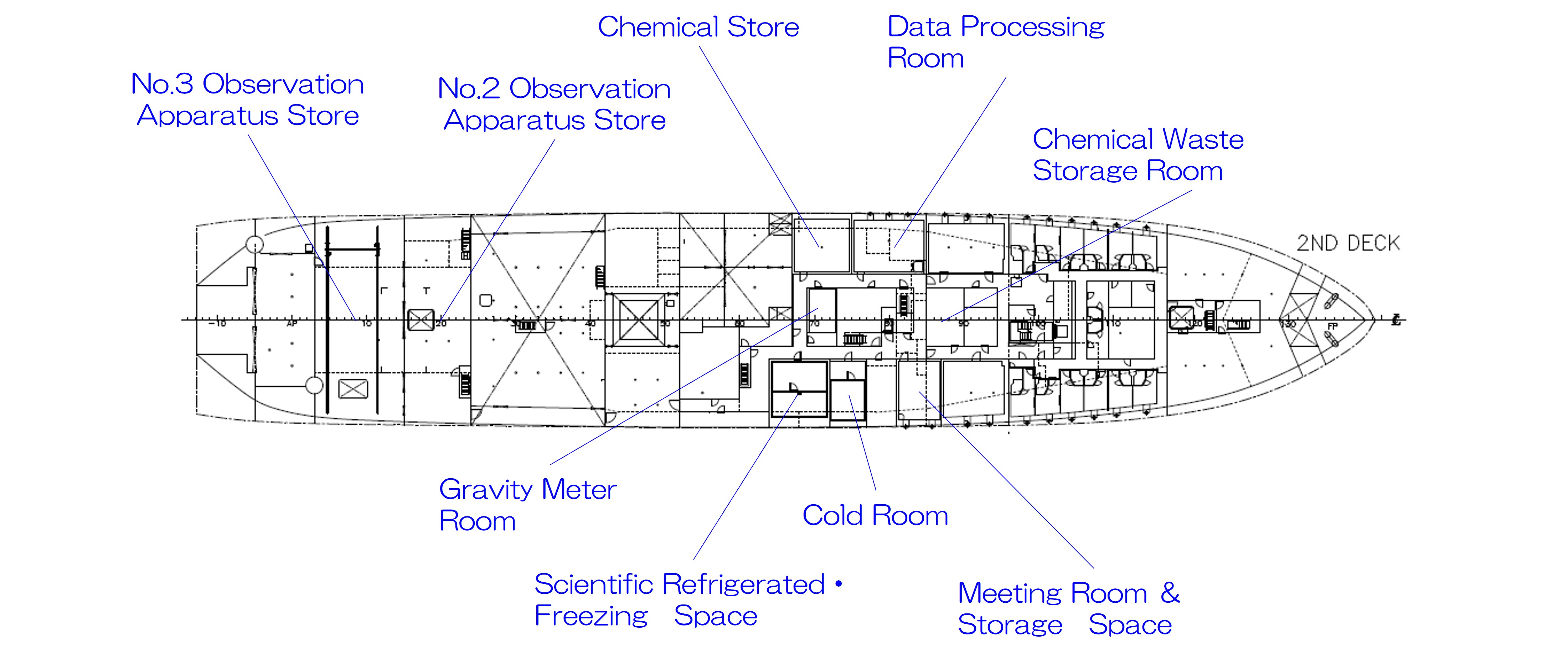

These figures above are a side view of the ship from the starboard side, a plan view of the upper deck (Equiv. to the first floor of a ground building) and the second deck (Equiv. to the basement level) from a drawing called a "General Arrangement " that shows the basic layout of the ship. These two decks are concentrated with lots of research and observation equipment.

Although there is still some more left that needs to be discussed, we believe that we nearly came to agree on the shape and size of the rooms and labs, plot allocation, location of major pillars, and placement of stairs and doors.

There have been some delays, but we have made it this far.

We would like to express our sincere gratitude to all the shipyards and construction supervisors who worked so hard daily under the circumstances of the global distribution slowdown and the COVID-19 pandemic.

However, we are not done yet!

The next major milestone to be executed in FY2023 is confirmation of the vessel’s design using a 3D digital mock-up and a 1/25 scale model.

We will review the images and models of the vessel from various perspectives and check for any problems by confirming three-dimensional movements, such as cable lines and routing, which are difficult to grasp from a plan view, as well as the movement of observation equipment and lifting methods by cranes.

While the shipyard designs the actual assembly of the ship in the factory (they call it "Production Design") at the same time. They cut the steel plates and weld small parts (even though they are big enough compared to the size of human beings), assembled them into large blocks, and stacked them to make the ship according to the production design.

These are an important process that requires accurate planning, taking into consideration the order in which the blocks are built, the schedule for stacking them, and the timing for installing large equipment such as piping, electric cables, and generators to be installed before the blocks are built.

(Thank you, shipbuilders, for your cooperation.)

We will continue to hold profound discussions, share ideas, and explore the best arrangement of research and observation facilities for actual onboard activities.

We would like to report on the deliberations using a model with the next status update, so please stay tuned!