DSV SHINKAI 6500

World-Class Submersible for Ultra-Deepwater Research

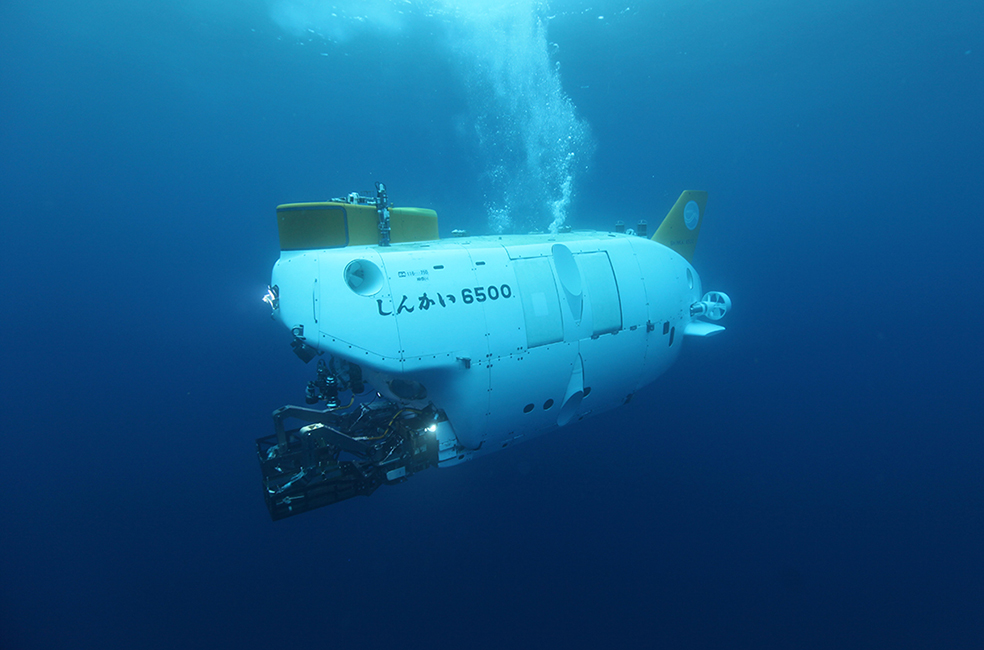

SHINKAI 6500 is a submersible research vessel capable of diving to a depth of 6,500 meters below the ocean’s surface. Based on previous experience with manned research submersible SHINKAI 2000, SHINKAI 6500 was built in 1990, and conducts research on the bathymetry and geology of the ocean floor, and deep-sea organisms; not only in the seas around Japan, but also in the Pacific, Atlantic, and Indian Oceans. Since its construction, SHINKAI 6500 ’s internal systems and research equipment have continuously been upgraded and continue to play a leading role as a pioneer in deep-sea research.

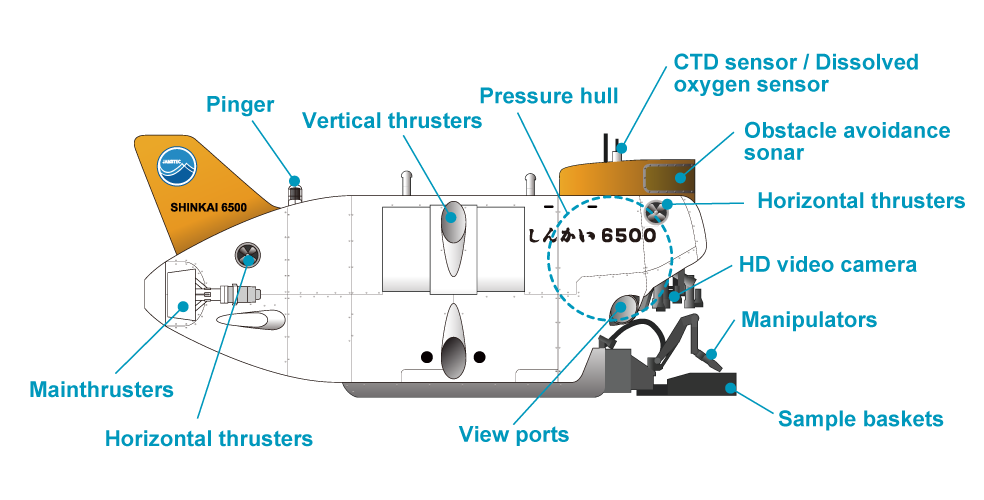

Main equipment

Equipped with the latest underwater acoustic technology

Land-based communications typically use radio waves, but these are “muted” underwater and do not travel as far, so sound waves are utilized instead. Sound waves usage has several benefits, such as checking the bathymetry of the seabed below, the position of the ship and communicating underwater with the Yokosuka mother ship. SHINKAI 6500 is also equipped with an image transmission system that sends color images taken by the underwater camera to Yokosuka via high-speed acoustic communication. The images are 240 x 320 pixels and are updated every two seconds, so researchers and technicians aboard Yokosuka are kept up-to-date on the status of SHINKAI 6500 below, which plays an important role in conducting research and safety.

Color images of the deep sea sent to Yokosuka mother ship.

Color images of the deep sea sent to Yokosuka mother ship.

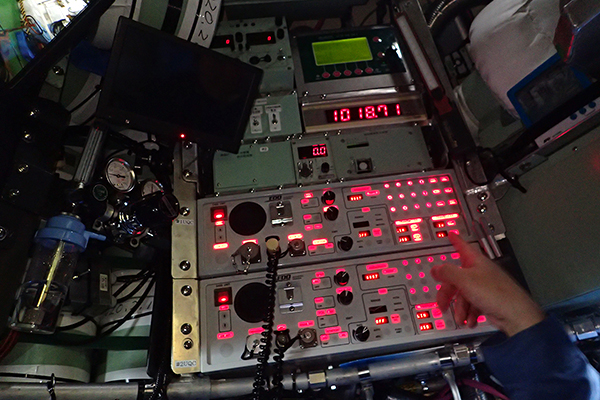

Underwater communication equipment on board SHINKAI 6500.

Underwater communication equipment on board SHINKAI 6500.

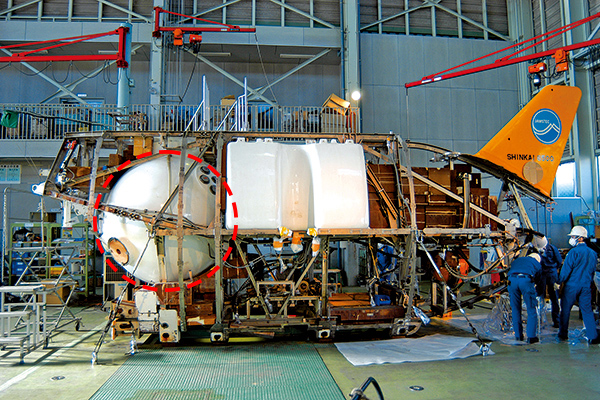

Under Pressure

A titanium alloy made pressure hull, with walls about 7 cm thick and a 2-meter inner diameter designed to hold a three-person crew plays a pivotal role in the central part of the SHINKAI 6500. SHINKAI 6500 's pressure hull is made to mimic a perfect sphere (with a sphericity of 1.004), a shape that is known to be the most resistant to external pressures, can withstand the water pressure at a depth of 6,500 meters. Extremely high levels of technological advancement and craftsmanship are required to achieve such results. Even a tiny defect in the spherical pressure hull can have a disastrous effect crushing the sphere and the crew within.

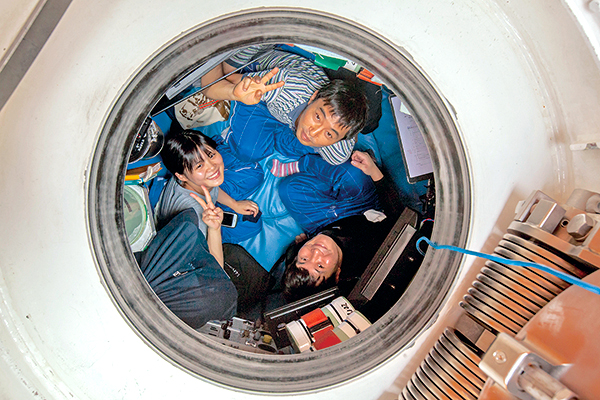

Inside of the pressure hull, the three-person crew has little room to stretch their legs freely.

Titanium-alloy pressure hull shell exposed for inspection (dotted line).

Titanium-alloy pressure hull shell exposed for inspection (dotted line).

View of the inside of the pressure hull from the hatch.

View of the inside of the pressure hull from the hatch.

Photography by Chong CHEN.